Introduction: How to Minimize Risk in Wholesale Purchasing

Buying jewelry micromotors in bulk can feel like a roll of the dice—especially when you’re juggling cost, quality, and performance. For jewelry businesses, these tools aren’t just nice-to-haves; they’re essential. A single breakdown can mean delays and unhappy customers. To dodge low-quality micromotors, you need a solid game plan. This guide lays out five practical tips to help wholesale buyers evaluate micromotor quality at every step of the process.

Tip 1: Quick Initial Screening & Sample Check

Key Focus:

Appearance: Check the finish, weight, and balance. A solid micromotor feels sturdy, with a smooth, even surface. Rough edges or shoddy craftsmanship? Red flags.

Basic Function Test: Fire up the motor for a quick run and listen closely. It should hum along smoothly—no grinding, whining, or clicking.

Why It Matters:

Spot Defects Early: Catching obvious duds upfront saves you time and cash.

First Impressions Matter: Sloppy build or odd noises hint at a lack of care in production.

Example:

Visual Check: A motor with rough edges or uneven weight distribution will likely have internal imbalances, which could cause vibrations or failure over time.

Noise Test: Grinding or clicking usually means bad bearings or an uneven rotor.

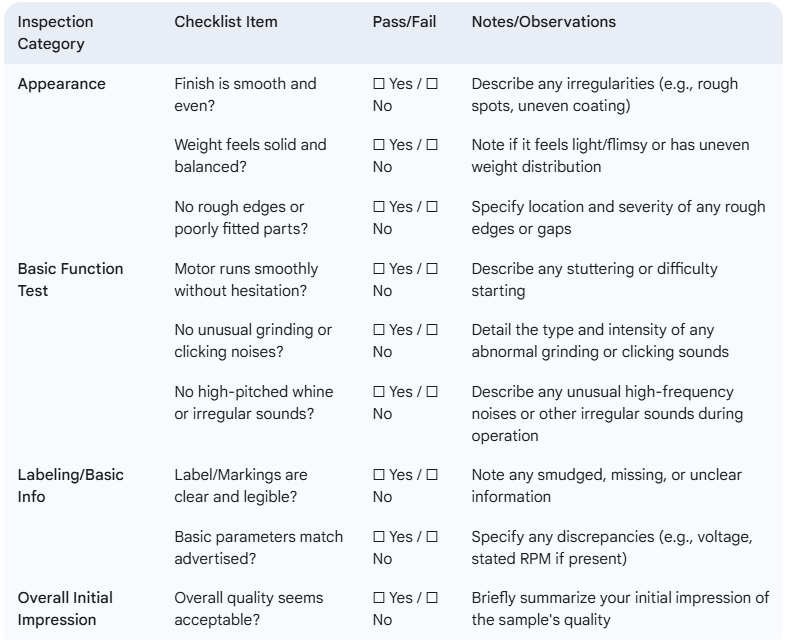

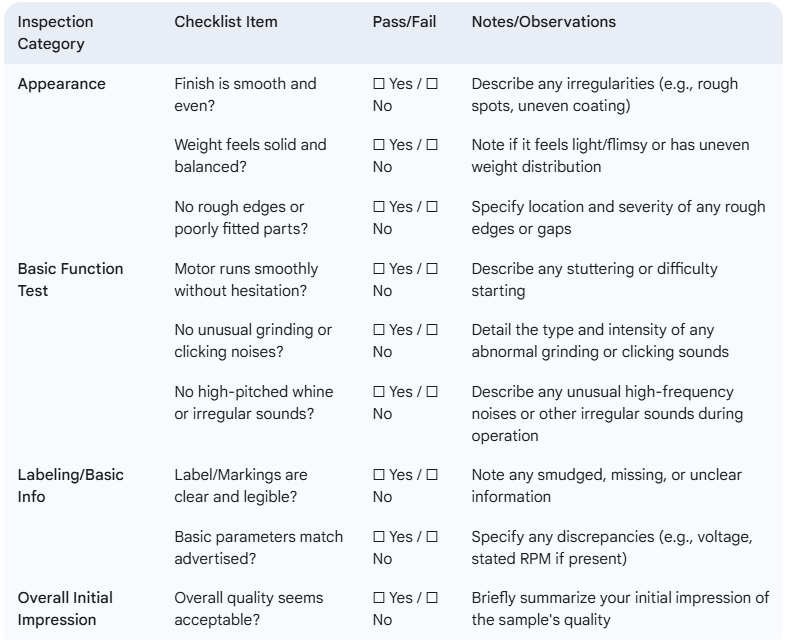

Visual Aid 1: Sample Inspection Checklist

Instructions: Grab each micromotor sample and run through the checklist. Mark "Yes" if it’s good, "No" if it’s off, and scribble notes about any problems. Too many "No" marks? Skip that sample for deeper testing.

Tip 2: Test Core Functionality & Comfort

Key Focus:

Torque & Load Handling: Put the micromotor through light to moderate tasks. It should hold steady power—no stalling or overheating.

Vibration & Noise Levels: Test it under load. Too much shaking or noise isn’t just irritating—it makes precision work tough.

Grip Comfort: Hold the handle. A good grip keeps your hand happy during long sessions.

Why It Matters:

Efficiency: You need a micromotor that tackles jewelry jobs—like drilling or polishing—without choking.

User Comfort: A shaky motor or awkward handle wears you out and risks ruining delicate pieces.

Example:

Torque Test: When testing the torque, ensure that the motor doesn’t stall or struggle with tasks like drilling or polishing, which require sustained power.

Grip Test: If the handle feels slippery after extended use, it may indicate low-quality materials or a poor ergonomic design.

Visual Aid 2: Torque & Vibration Comparison Chart

Instructions:

- Torque (mNm): Use appropriate testing equipment to measure the torque output of each jewelry micromotor sample under a consistent light load. Record the values in the chart. Establish an acceptable minimum torque benchmark based on your application needs.

- Vibration Level (RMS m/s²): Use a vibration meter to measure the root mean square (RMS) vibration levels of the handpiece while the motor is running under the same light load. Record the values. Define an acceptable maximum vibration level for comfortable and precise operation.

- Noise Level (dB): Use a sound level meter to measure the noise produced by the motor while running under the light load. Record the decibel levels. Establish an acceptable maximum noise level to ensure a comfortable working environment.

- Grip Comfort (Scale: 1-5): Evaluate the ergonomic design and comfort of the handpiece grip on a scale of 1 to 5, where 5 represents the most comfortable grip. This is a subjective assessment but important for user experience. Define a minimum acceptable comfort level.

- Acceptable Range/Benchmark: Fill in the "Acceptable Range/Benchmark" row with the minimum acceptable torque, maximum acceptable vibration and noise levels, and minimum acceptable grip comfort score based on your requirements.

Interpretation: Compare the measured and assessed values for each sample against the established acceptable ranges or benchmarks. Samples falling outside these ranges may indicate lower quality or performance issues. This chart helps in a comparative analysis of different jewelry micromotors.

Tip 3: Check Key Components & Specifications

Key Focus:

Motor Components: Focus on critical parts such as bearings, carbon brushes, and stator windings. Low-quality components will wear out faster and lead to premature motor failure.

Motor Specs: Cross-check the specifications, such as RPM, torque, and voltage, against the supplier's claims. Ensure the motor's performance matches your needs.

Why It Matters:

Long-Term Durability: Components like bearings are highly susceptible to wear and tear. A motor with subpar bearings or brushes will degrade quickly.

Ensuring Expected Performance: Verifying the specifications ensures the motor meets your operational requirements and avoids performance issues.

Example:

Bearings: Low-quality bearings may cause friction and noise, reducing the motor’s lifespan and accuracy.

RPM Check: Ensure the RPM is consistent with the specifications. A motor with a lower-than-advertised RPM will perform poorly on high-precision tasks.

Visual Aid 3: Technical Comparison Table

Column Explanations:

• Item: The key component or specification being checked.

• Supplier Claim: The value or description provided by the supplier.

• Measured/Observed: The actual value measured or observed.

• Pass?: Whether the measured/observed value meets the supplier's claim and your requirements (Yes/No).

• Notes: Detailed observations or comments.

• Importance: The criticality of this item (High/Med/Low).

How to Use:

- List the key components and specifications. Fill in the "Supplier Claim."

- Perform tests and inspections, recording the "Measured/Observed" values.

- Evaluate if each item "Passes?" based on your criteria.

- Add detailed "Notes" as needed.

- Pay close attention to items with "High" importance.

Tip 4: Sample Performance Consistency & Testing Limits

Key Focus:

Sample Consistency: Test a handful of samples. They should all perform alike—big differences mean trouble.

Stress Test: Push it harder or run it longer. Watch for overheating or breakdowns.

Why It Matters:

Batch Quality : Uneven samples point to sloppy manufacturing.

Reliability : A micromotor that wilts under pressure won’t last when it counts.

Example:

Consistency Test: If half your samples flop, quality control’s probably a mess.

Load Test: Overheating or extra noise under stress shows it’s not built tough.

Visual Aid 4: Performance Consistency Chart

Displays the performance (speed, noise and temperature) of 10 different samples of the same motor model

Explanation of the Data:

• Sample: Identifies each of the ten motors tested.

• Speed (RPM): The rotational speed of the motor in revolutions per minute.

• Noise (dB): The sound level produced by the motor in decibels.

• Temperature (°C): The operating temperature of the motor in degrees Celsius after a certain period of testing (under a consistent load for the consistency test).

Tip 5: Audit Supplier & Establish a Quality Agreement

Key Focus:

Supplier Reputation: Dig into their track record and reviews. A solid supplier with happy clients usually delivers.

Quality Agreement: Nail down a contract with specs, quality checks, and return terms. Settle on an acceptable defect rate (AQL).

Why It Matters:

Trustworthy Suppliers: A good one keeps quality steady and backs you up.

Legal Protection: A clear agreement means no surprises if things go south.

Example:

Supplier Reputation: Bad reviews or slow replies? They might flake on quality, too.

Quality Agreement: An AQL keeps the supplier accountable to your standards.

Visual Aid 5: Supplier Audit Checklist

Instructions for Use:

- Category: Key areas to judge the supplier.

- Key Metric: What to measure in each.

- Compliant (Yes/No/NA): Check off based on what you find.

- Notes: Jot down specifics or next steps.

- Priority: Focus on the big-ticket items.

Conclusion: Streamlined Risk Management for Wholesale Buyers

Stick to these five tips—pair them with solid testing and supplier vetting—and you’ll cut your risks big time. You’ll land high-quality jewelry micromotors that deliver value: reliable, tough tools that match your business demands.

Visit RHJC for Premium Jewelry Micromotors

If you're looking for high-quality jewelry micromotors with guaranteed performance, RHJC offers a wide range of products tailored to the needs of professional jewelers and manufacturers. With years of experience and a commitment to innovation, we provide motors that are reliable, durable, and perfect for your jewelry-making needs.

Visit our website at www.rhjc-cn.com to browse our selection, get in touch with our team, and learn more about how we can support your business with top-quality jewelry micromotors.